Technoparts has a division specialized in Shell and tube heat exchanger inspection. Nowadays we have technicians with ASNT certification for Eddy Current Test in tubes and APR (Acoustic pulse reflectometry). As a complementary service, we can offer inspection by videoscope and vacuum leak test in each tube.

Our teams are available for services all over Latin America with agility in traveling and fast answers for inspection, using equipment from Zetec, Uniwest, Acoustic Eye Extech and Curtiss Wright.

If your company are interested in our services, please send us complete information of your heat exchanger and we can offer you a solution according the best inspection technology.

Eddy Current inspection

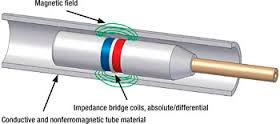

Eddy current inspection is one of several NDT methods that use the principles of electromagnetism as the basis for conducting examinations.

Eddy current inspection can be used to find finest surface and subsurface flaws in any conductive material with very good results. It has a good speed of inspection with almost 200 tubes/hour depending the situation of the heat exchanger.

Basic technique:

A probe is inserted in each tube with an electromagnetic wave crossing the thickness

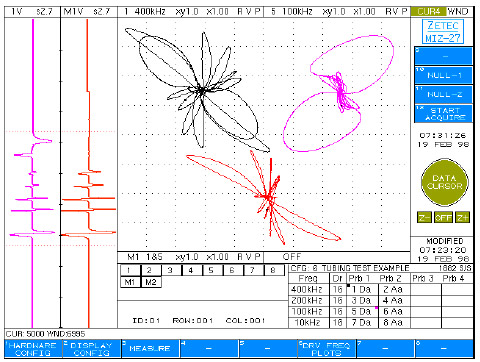

Signals are collected and analyzed by the equipment to check defects:

Some of the advantages of eddy current inspection include:

- Sensitive to small cracks and other defects

- Detects surface and near surface defects

- Inspection gives immediate results

- Equipment is very portable

- Method can be used for much more than flaw detection

- Minimum part preparation is required

- Test probe does not need to contact the part

- Inspects complex shapes and sizes of conductive materials

Technoparts uses ZETEC and Uniwest equipment for ECT. We have a stock of probes and tube standard to cover major tube specification of the market.

Acoustic Pulse reflectometry – APR

AcousticEye’s breakthrough, non-invasive solution for today’s hard-to-inspect tubes up to 4” inner diameter enables ultra-fast, accurate inspection of boilers, Fin Fans and other heat exchangers, regardless of tube shape or material.

Featuring patented Acoustic Pulse Reflectometry (APR) technology, Dolphin G3™ is an advanced, yet easy-to-use tool that overcomes the limitations of many conventional inspection techniques. With its simple operation, automated analysis and report generation, there is far less dependency on operator expertise.

Providing reliable inspection of even the most challenging tube sizes and configurations, AcousticEye increases inspection cycle efficiency and operational cost savings.

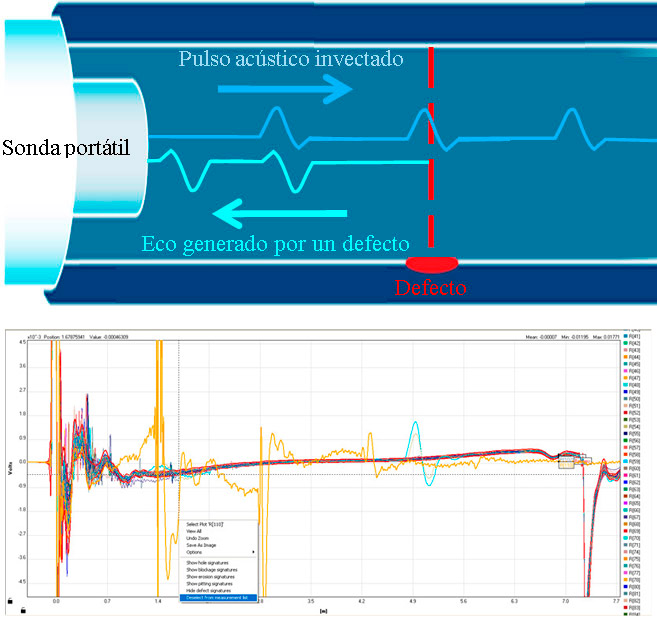

Inspection Technique:

- Probe injects an acoustic pulse down the tube

- Returned echoes generated by defects are recorded and analyzed

- A set of proprietary, patented algorithms identifies and reports, exact location, type and size of inner diameter defects

Main advantages:

Any tube size up to 4” diameter, regardless of shape or material

Boilers, Fin Fans, other heat exchangers, U-bends, twisted and spiral wound tubes Ferrous and non-ferrous metals, graphite and plastics.

Ultra-fast, non-invasive inspection

- Less than 10 seconds per tube

- Fast enough for 100% inspection if/when needed

- Ideal for emergency situations

- No need for inventory of consumable probes or standards

Videoscope and vacuum test leak detector

Technoparts offer complementary service with inspection that is videoscope inspection and vacuum leak test for tubes.

For the videoscope inspection we use Extech instruments with high resolution image to check inspection results or complementary inspection in tubes and others.

Vacuum leak test

One person can easily do the job. Just seals the far end of each tube with a snap-type tube plug, presses the Vacuum Leak Detector’s rubber-coated nozzle into the near end of the tube and depresses the trigger. Compressed air flows through a venturi chamber to produce a vacuum in the tested tube. When this vacuum reaches a satisfactory level, he releases the trigger. A steady gauge reading indicates a good tube. A falling vacuum indicates a leaky tube. Using 90 psi dry, clean air, it only takes six to eight seconds to test a typical tube (1-inch Outer Diameter x 20 gauge and 20 feet long) with the Vacuum Leak Detector. The tool weighs 2 1/4 lbs. and is equipped with a muffler, so it operates quietly even in confined areas.

Technoparts has technicians for this job or could sell the complete kit for inspection. Please get a contact with us for complementary information.